No matter what type of electrical equipment you own, the constituents will break down over time and lose efficiency. Equipment failure can cost you hundreds or thousands of dollars in maintenance and downtime of your business. In this article, we’ll discuss what infrared electrical inspections are, how they work, and how to determine if your equipment should be tested.

What is an Infrared Electrical Inspection?

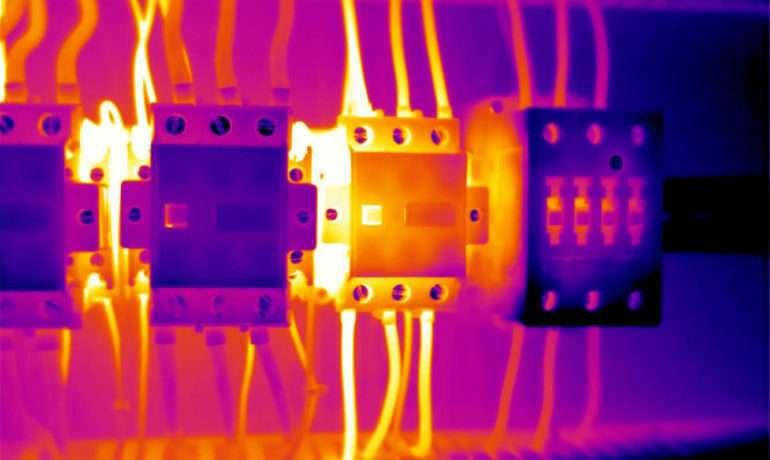

An infrared (IR) electrical inspection is able to detect radiant heat levels of your equipment while it runs. Electrical components frequently emit excessive heat when they become loose, dirty, damaged, or less efficient, so an IR test can be used to predict when equipment failure is likely in the future.

How Often Should It Be Done?

Generally speaking, the more frequently you have IR testing completed, the sooner you’ll detect problems and be able to have them repaired. The general rule of thumb is that you should have an IR inspection done once a year, but many business owners have them carried out more frequently on older equipment that is more likely to break down.

What Is Tested?

Any piece of equipment that uses electricity can be tested with an IR electrical inspection. Common devices and components that can be tested include transformers, electrical circuitry, motors, solar panels, switchboards, and service panels.

The diagnostic can also be used to find inefficiencies in mechanical equipment, including motors and building utility systems.

Benefits of a Test

There are numerous benefits to IR inspections, the most significant of which is that your equipment doesn’t need to be shut down to diagnose issues. In fact, IR testing relies on your equipment running to identify problems, so your business will experience no downtime.

IR testing can predict severe damage and assess the risk of unscheduled downtime, potentially saving you thousands of dollars in equipment maintenance and property damage, as well as your employees’ or customers’ lives.

Signs Your Equipment Should Be Tested

Although you should have your equipment tested annually, there are some signs that you should schedule an inspection sooner. These include unusual noises coming from your devices during operation, enclosures that are hot to the touch, or uncharacteristically high electric bills resulting from inefficiencies in your equipment.

IR inspections are a fast and cost-effective way to minimize maintenance costs for your electrical or mechanical equipment while eliminating your business’s unscheduled downtime. When you’re ready to schedule an infrared inspection for your company’s devices, contact one of our highly-trained professionals for more information.