When it comes to testing equipment in your business or building that carries high electrical charges, proper safety protocols can be the difference between life and death for technicians. Having the proper type of testing available can also prevent major electrical outages and help you save money on your testing and maintenance. Below, we’re discussing one of the easiest and most efficient ways to make your electrical equipment safe and easy to test, as well as some of the advantages associated with infrared windows.

What are Infrared (IR) Windows?

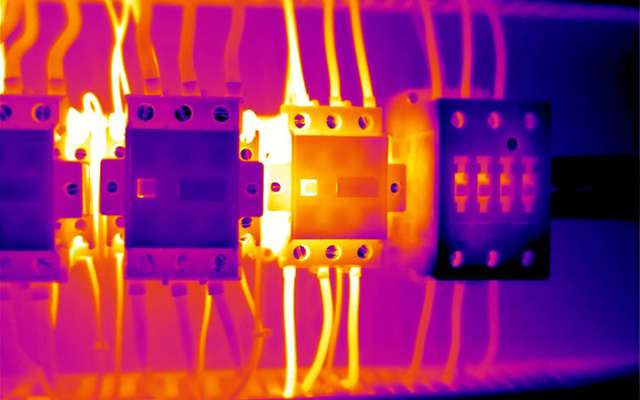

An infrared window is a very carefully crafted viewing “window” that allows for highly-charged electrical equipment to be inspected and tested for proper functionality without exposing a technician to severe danger.

IR windows include viewing panes, which allow the equipment to be inspected through a lens. They include grills, which allow heat transfer naturally while helping to maintain safety. They also offer inspection ports for scanning with an IR scanner and other custom solutions for unique equipment.

How Do They Work?

Regardless of the type of IR window used, they are designed to allow a trained technician to test your electrical equipment for failure, damage, malfunction, or potential problem without opening the electrical box and exposing themselves to the extremely dangerous and highly-charged cables or coils.

What Are the Benefits of IR Windows?

IR windows bring huge benefits to property owners, electric technicians, and inspectors. Below are the top four benefits of using IR windows on your equipment.

1) Perform Inspections on Electrical Equipment – of course, one of the biggest benefits to an IR window is that it allows you to have inspections performed on your equipment. IR windows allow access for testing that can help identify issues early before they cause major personal harm or severe property damage.

2) Collect Real-Time Data – with highly-charged electrical equipment, it’s typically unsafe to test it under full load and in real-time. However, because IR windows allow for far safer testing, collecting real-time data while your system is under full load is possible. This possibility allows for more accurate testing and better results from inspections.

3) Protect Electrical Workers from Injury or Death – electricity can be extremely dangerous, especially when equipment is under full load and carrying high charges. IR windows help protect inspectors and electrical workers from injury or death from shock while they work to ensure your system is functioning properly.

4) Save Money – lastly, IR windows can prevent thousands of dollars in losses to your business due to electrical outages and equipment failure by allowing for safe testing and help identify potential issues, keeping your business up and running and your equipment and property safe.

It’s clear that IR windows can drastically improve the safety of your business and the safety of the technicians who keep your electrical equipment working properly. When you’re ready to install IR windows at your business, contact one of our infrared inspection experts to discuss how IR windows can benefit you, your employees, your equipment, and your property.